Stockouts allow us to track product availability across stores and assess the quality of the replenishment. Below is the definition of the two stockout levels available.

Absolute stockout

This KPI measures how many SKUs of the assortment are not available at a given time. The absolute stockout level ranges between 0% and 100%.

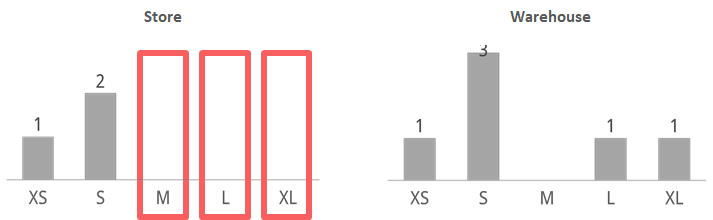

Let's see an example. Let's say we have a product with 5 sizes and we are missing 3 of them. In this case the absolute stockout will be calculated as 3/5 = 60%.

Real stockout

This measures the SKUs missing from the assortment that could have been avoided because there are units left at the wharehouse. This the quality of the replenishment level to be tracked. Note that a certain degree of real stockout is required to keep a balanced service level across stores. The real stockout level is equal to or less than the absolute stockout level.

To calculate the real stockout level we follow the same logic as with the absolute stockout, with one difference; we do not consider SKUs without enough stock in the warehouse to replenish all the missing SKUs across the store network.

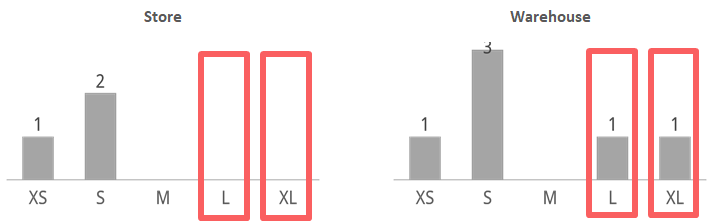

Let's see an example. We have a store with a product with 5 sizes, from which 3 are missing. However only two are sufficiently available in the warehouse. In this case the real stockout is 2/5 = 40%.

.png?height=120&name=Nextail-logo-rojo%20(5).png)