The Replenishment module allows stock to be sent to each store of an existing product in warehouse.

The algorithm in this module is based on some principles that help us understand how it works:

- Demand

All calculations are based on the sales probability of an item in each store each day.

- Global optimization

The replenishment cycle is calculated as a whole, to achieve the global optimum.

- Robustness over accuracy

Avoiding big mistakes takes precedence over increasing accuracy in most cases.

- Meritocracy

The starting point of the replenishment calculation is the existing stock, not store demand.

- Rich constraints set

Several types of constraints can be configured and considered.

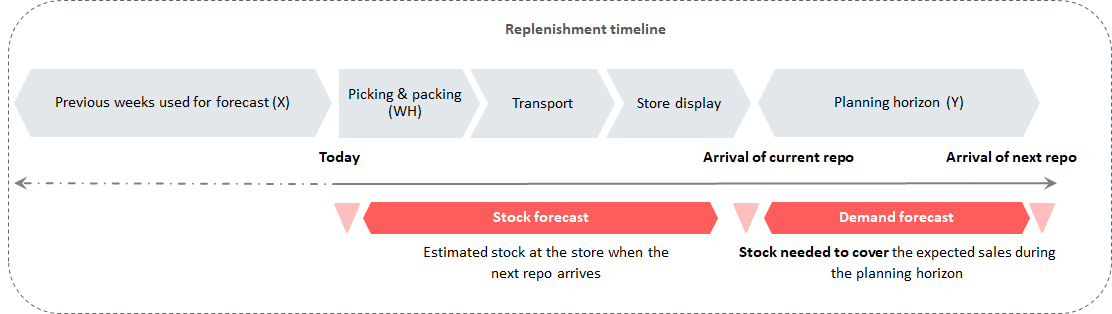

To cover the expected demand for a certain period of time (Planning Horizon), Nextail determines how much stock is needed.

- The number of units of each SKU to send to stores is calculated to cover the expected demand with a high degree of probability until the end of the “Planning Horizon".

- In case of scarcity, units are distributed in a way that maximizes total expected sales.

Read more about:

Replenishment algorithm: Forecast

Replenishment algorithm: Optimization

.png?height=120&name=Nextail-logo-rojo%20(5).png)